How we helped deliver Australia's first LNG import terminal

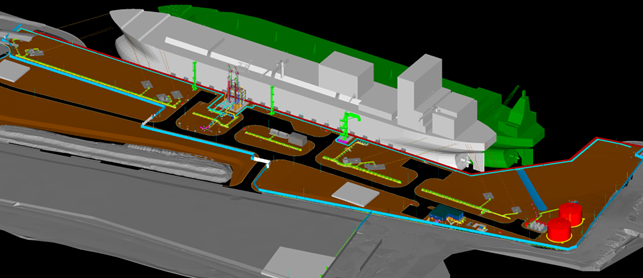

Our involvement in Australia’s first LNG import and regasification terminal began with a clear challenge: engineer a safe, high-performance onshore facility to receive LNG imports and connect them to the East Coast gas network.

The Port Kembla LNG Import Terminal gas supply now supports energy supply stability through a seamless offshore-to-onshore transition, enabling LNG to be regasified offshore via a permanently moored floating storage and regasification unit (FSRU) and seamlessly integrated into the national pipeline system through robust onshore infrastructure.

Delivering Critical Infrastructure

In Q3 2023, Verbrec completed the detailed engineering design for the Onshore Receiving Facility (ORF)—the critical link between the moored FSRU and the national gas grid.

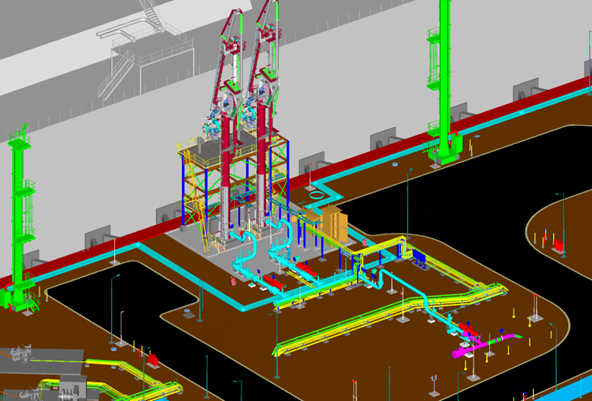

Our scope included the detailed design, engineering, modelling, and drafting of all ORF systems, including utilities, fire safety infrastructure, civil roads and drainage, non-process infrastructure, and key control systems.

*

We applied a multidisciplinary team approach across process, mechanical, civil/structural, E&I, and fire safety engineering. Risk and constructability were embedded from the outset, with active facilitation of HAZOP, HAZID, Safety in Design, and constructability review workshops at all major milestones.

We also supported construction and commissioning with the development of as-built documentation and direct procurement support across a wide range of packages, from firewater pumps and nitrogen supply to control systems equipment and diesel unloading facilities.

Engineered for a Firming Energy Future

Through precision engineering, risk management, and careful procurement planning, we ensured that the facility was built to meet Australia’s stringent regulatory, operational, and safety standards.

Our early involvement in project development allowed for deep integration with project stakeholders, resulting in more efficient design outcomes, reduced costs, and an accelerated delivery schedule.

Multidisciplinary

Design

Full ORF design: process, mechanical, civil, fire, E&l, and controls.

Quantitative Risk Assessment

QRA covering core infrastructure and risk modes.

Safety

Leadership

Led HAZOP, HAZID, and constructability review at key milestones

A comprehensive Quantitative Risk Assessment (QRA) was undertaken to identify and mitigate hazards across all critical infrastructure.

This included:

- LNG tankers and FSRU operations

- Gas pipelines, pig launchers, and utility tie-ins

- Storage systems for odorant, diesel, and firewater

By covering both high-and low-demand scenarios, we ensured a resilient design aligned with regulatory compliance and public safety standards.

- Today, the Port Kembla LNG Import Terminal stands as cornerstone in Australia’s evolving energy mix. By enhancing supply flexibility and security, it strengthens the East Coast network and helps position the nation to meet future energy demands safely, reliably and sustainably."