Through strong relationships built on trust, Verbrec continues to transform assets and people for a sustainable and smarter future.

Sustainable, smart and innovative, this is Verbrec’s motto and DNA. Through acquisitions, continuous improvement and innovation, this industry leader has expanded its capabilities significantly to support its clients’ needs and built what it is today, a leading engineering, asset management, infrastructure, and training company operating across the entire asset life cycle.

The company has more than 700 professionals dedicated to innovative thinking and exceptional client service, operating across Australia, New Zealand, Papua New Guinea, and the Pacific Islands. Verbrec brings together several well-established companies, including LogiCamms and OSD, which individually have a strong track record of delivering specialised services to the energy, mining and infrastructure industries since 1988. Representing the company’s evolution and continued growth, it has by leveraged emerging techniques and technologies for the benefit of its clients.

In line with Verbrec’s vision to engineer transformative solutions, the company is committed to playing its part in the decarbonisation of the energy mix, facilitated by renewables and alternative fuels, such as hydrogen and biogases. It has already played a significant role in several important and innovative projects which leverage technology and innovation to facilitate emissions reduction.

As part of the company’s transformation, Verbrec has also welcomed a new Chief Executive Officer (CEO), Mark Read.

He will take over from Linton Burns, who last year announced his retirement from the roles of CEO and Managing Director.

Read has more than 30 years’ experience working for publicly listed and privately held engineering service companies across the globe and has a proven track record of leadership, management and change management of technical services and project delivery organisations.

“I am honoured to have been selected to take over the helm of a company with the capability and heritage of Verbrec at such an opportune time,” says Read.

“Verbrec is now ideally positioned to expand its current client offerings as well as developing new markets, particularly within the renewable energy and digital technology fields.

“I look forward to delivering on the next stage in the evolution of Verbrec – building upon our purpose, increasing the brand’s value and enhancing the environment in which talented people can grow and flourish as well as strengthening our client relationships and delivering value to shareholders.”

The Mahalo north gas supply expansion feed study

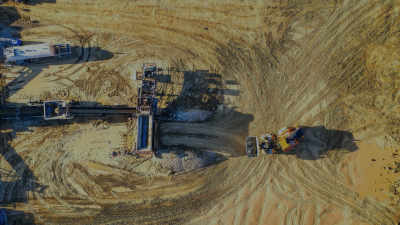

Verbrec has won a front-end engineering study from Denison Gas for its proposed infrastructure expansion to accommodate gas from Comet Ridge’s planned Mahalo North gas development. Denison says the front end engineering and design (FEED) work, jointly funded with Comet Ridge, is to prepare a design, project schedule and budget to upgrade its production infrastructure to accommodate 10 terajoules (TJ) per day of gas from Mahalo North, located in Queensland.

The purpose of the FEED is to determine a project schedule and budget through the development of the process, mechanical, civil/structural, and electrical and instrumentation design of the proposed brownfield modification to the Denison Facilities. The gas from Comet Ridge’s Facility will be supplied by pipeline to Denison. Once results of the FEED study are finalised, Denison and Comet Ridge intend to execute commercial arrangements which Denison will compress, dehydrate, and transport Mahalo North gas production for delivery into the east coast market.

Kupe Oil system energy efficiency improvement study

Beach Energy has contracted Verbrec to complete an energy improvement study of its Kupe Oil System in Taranaki, New Zealand.

Beach is the operator of the Kupe Natural Gas Processing Plant which produces gas from the Kupe Field, situated approximately 30 km offshore New Zealand’s North Island.

Kupe is critical to the country’s energy infrastructure, providing 15 per cent of the country’s gas and 50 per cent of its LPG during peak periods.

The ‘Kupe Oil System Energy Efficiency Improvement Study’ will be completed by Verbrec’s Engineering Services division, which provides innovative engineering and project delivery solutions to clients through its technical specialties including digital industry, power, process plant, pipelines and asset management.

For the study, the company will conduct analysis of process engineering and conclude options for efficiency; complete mechanical and piping engineering to high level equipment specifications; and engineer instrumentation and electrical for the preliminary identification of control elements.

LaTrobe Valley HESC pilot plant control

Verbrec played a role in the world’s first shipment of liquified hydrogen (LH2) from Australia to Japan. The LH2 was produced at a plant in the LaTrobe Valley which is part of the Hydrogen Energy Supply Chain (HESC) pilot project, aiming to produce 225,000 tonnes of the fuel each year.

Verbrec, in collaboration with GHD and J-Power, provided the main control system components at the plant where the hydrogen was produced, including the Programmable Logic Controller (PLC) and Supervisory Control and Data Acquisition (SCADA). Singling out the engineering and commissioning teams for their contribution to the watershed moment.

In January 2022, the LH2 was transported by specially built LH2 carrier, the Suiso Frontier, from the Port of Hastings, Victoria, to Kobe, Japan. The Japanese and Australian governments are supporting the $500 million HESC project. HESC estimates the volume of hydrogen produced by the project will help reduce global emissions by approximately 1.8 million tonnes per year.

Hydrogen refuelling station trial

The scope of this recently completed project includes the technical assessment of vendor packages, a safety hazard and operability (HAZOP) study, hazard identification facilitation, as well as location assessment and general arrangement of the refuelling station.

In addition, Verbrec managed the integration of the electrical and instrumentation, controls and telecommunications; the civil and structural design; process and operations support; hazardous area classification and drawings; and managed regulatory approvals. The scope further includes a detailed review and assessment of the vendor package to ensure it meets all legislative requirements for installation in NSW.

In 2021, Verbrec was engaged by one of Australia’s largest energy operators and asset owners to support the detailed design and engineering of a hydrogen refuelling station in New South Wales. The company was tasked with defining, and supplying all engineering deliverables required to install, integrate and safely operate the refuelling station to applicable standards. The construction of the station was part of a 12-month trial to power a bus using hydrogen, which will be fuelled from a third party H2 tube trailer.

QLD hydrogen pilot program

Verbrec was involved in the construction of one of Queensland’s first green hydrogen generation facilities. Powered entirely from solar, the facility was setup as a demonstration pilot program.

Verbrec provided engineering support for the construction and commissioning of the system which comprised a pressurised water electrolyser unit and a purification unit providing hydrogen at the required purity for use in fuel cell generators and electric vehicles. It also included a solidstate storage unit to store hydrogen at low pressure by adsorbing it into a specially designed substrate.

Verbrec ensured the design of the system complied with Australian regulations and standards for process modules. In addition, the company managed design verification and registration of pressure vessels, the HAZOP of the interconnection of process modules to ensure safe operation and designed the vehicle fuel loading, as well as completing the development application for traffic, parking and stormwater infrastructure.

This article was developed in collaboration with PPO Projects at the time of publishing.